She had a clear vision but no clarity on technical execution — especially fabric innovation and design.

Las

Loungewear

Premium travelwear that redefines comfort and sophistication.

MODERN. FUNCTIONAL. TIMELESS.

Visit WebsiteOur Client

Las Loungewear, Premium Travelwear Brand

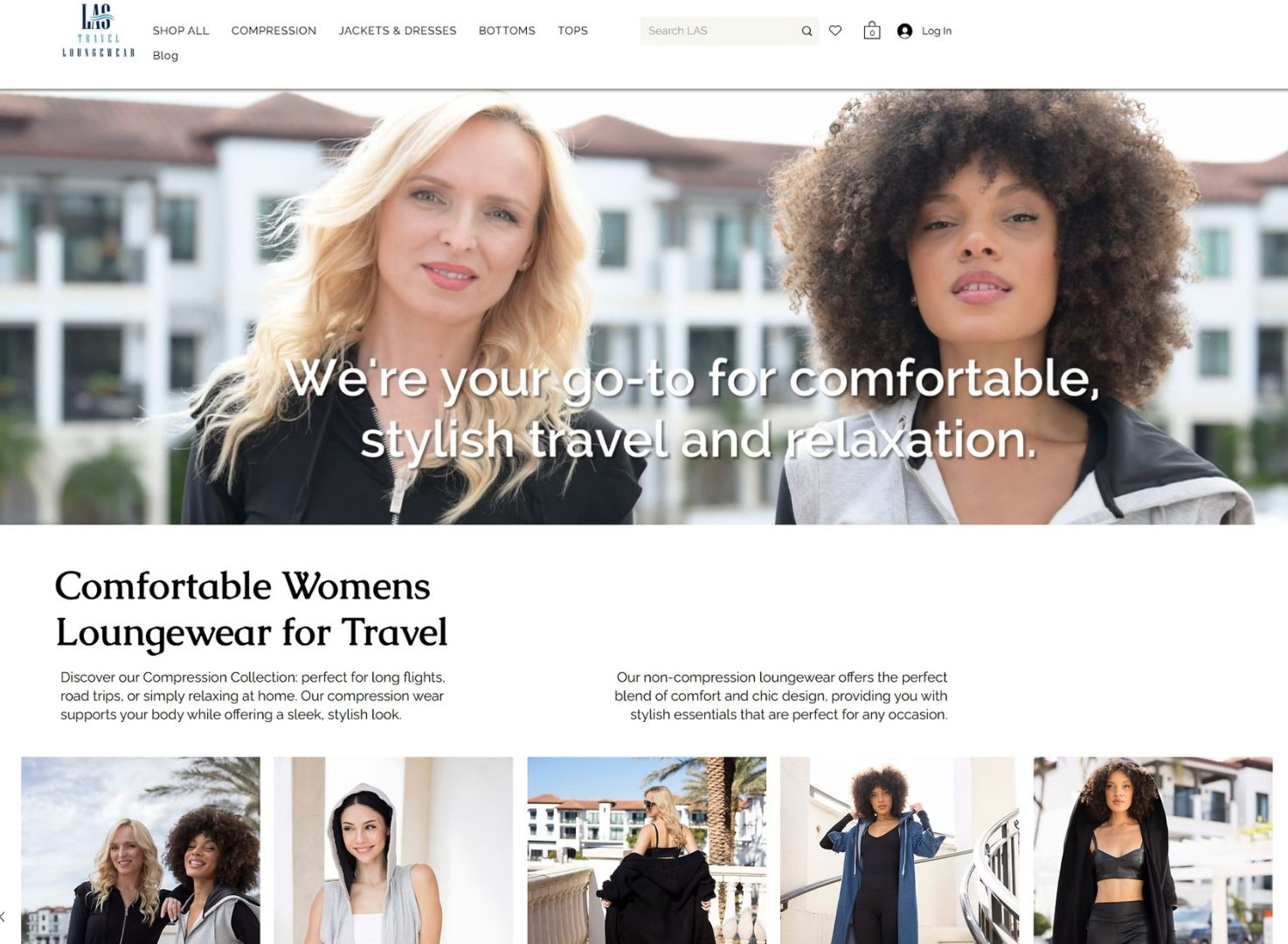

Las Loungewear emerged from a vision to create premium travelwear that seamlessly blends comfort with sophistication. The brand recognized that modern travelers demand more than just functional clothing — they seek pieces that elevate their journey while maintaining the highest standards of comfort and style.

The challenge was clear: how to design loungewear that feels luxurious enough for high-end hotels and private jets, yet comfortable enough for long-haul flights and extended travel. Las needed pieces that could transition effortlessly from airport lounges to hotel suites, embodying the essence of modern luxury travel.

The brand's commitment to premium materials, thoughtful design, and timeless aesthetics required a partner who could translate this vision into production-ready pieces that would meet the exacting standards of luxury travelers worldwide.

Our Client

Las Loungewear, Premium Travelwear Brand

Las Loungewear emerged from a vision to create premium travelwear that seamlessly blends comfort with sophistication. The brand recognized that modern travelers demand more than just functional clothing — they seek pieces that elevate their journey while maintaining the highest standards of comfort and style.

The challenge was clear: how to design loungewear that feels luxurious enough for high-end hotels and private jets, yet comfortable enough for long-haul flights and extended travel. Las needed pieces that could transition effortlessly from airport lounges to hotel suites, embodying the essence of modern luxury travel.

The brand's commitment to premium materials, thoughtful design, and timeless aesthetics required a partner who could translate this vision into production-ready pieces that would meet the exacting standards of luxury travelers worldwide.

THE VISION

Las Loungewear Vision

The client envisioned creating comfortable yet stylish travelwear — garments that felt as good as they looked. She wanted pieces that supported the body during long hours of travel, ideally using compression fabrics to reduce body pain and discomfort. While she didn't have exact clarity on fabrics or silhouettes, she knew she wanted a blend of chic aesthetics and functional comfort — something modern women could wear while traveling and still feel confident, relaxed, and put together.

THE VISION

Las Loungewear Vision

The client envisioned creating comfortable yet stylish travelwear — garments that felt as good as they looked. She wanted pieces that supported the body during long hours of travel, ideally using compression fabrics to reduce body pain and discomfort. While she didn't have exact clarity on fabrics or silhouettes, she knew she wanted a blend of chic aesthetics and functional comfort — something modern women could wear while traveling and still feel confident, relaxed, and put together.

The Challenge: What Was Standing in Her Way?

The journey from luxury vision to premium travelwear brand revealed complex challenges that required innovative solutions.

Traditional factories refused to work on small MOQs with high style variety.

Compression fabrics that felt soft and breathable were hard to source in limited quantities.

Design-to-production guidance was missing — there was no single team who could handle concept, sampling, and scaling.

There was a gap in understanding between client vision and garment execution.

Lack of transparency, delayed communication, and fragmented supply chains added to the frustration.

Was not getting hands-on creative partner who could translate her idea into real garments — with a balance of fashion and functionalist.

Was not getting a design-led process that included sampling, sourcing, prototyping, and production under one roof.

Wanted fashion-forward travelwear, not basic athleisure — but most vendors didn't understand that aesthetic.

Multiple fabric trials were needed, but most vendors didn't want to go through repeated R&D.

She was not getting a partner who believed in the idea enough to experiment, rework, and get every detail right.

A team ready to do deep R&D on fabrics like compression knits, bamboo, and cotton blends tailored for comfort and support.

Enter Krazy Kreators

Our End-to-End Approach

We became more than a vendor — we became her brand-building partner. From the first sketch to final production, Krazy Kreators managed every step, aligning her vision with a practical execution strategy.

Key Services Provided:

- Creative Direction & Moodboarding

- Custom Fabric Development

- Design Sketching & Style Planning

- Sampling & Fit Trials

- Small Batch Production

- Packaging & Brand Touchpoints

Enter Krazy Kreators

Our End-to-End Approach

We became more than a vendor — we became her brand-building partner. From the first sketch to final production, Krazy Kreators managed every step, aligning her vision with a practical execution strategy.

Key Services Provided:

- Creative Direction & Moodboarding

- Custom Fabric Development

- Design Sketching & Style Planning

- Sampling & Fit Trials

- Small Batch Production

- Packaging & Brand Touchpoints

The Creative Direction

Designing the DNA of Her Brand

Creative Direction & Moodboarding

We began by understanding her brand story and the emotional core behind her idea — stylish yet supportive travelwear. Since she didn't have exact clarity on silhouettes or fabrics, we stepped in to define a creative direction grounded in trend and data.

This gave her a visual language for her brand, bridging what she felt with what could be created.

Creative Direction & Moodboarding

We began by understanding her brand story and the emotional core behind her idea — stylish yet supportive travelwear. Since she didn't have exact clarity on silhouettes or fabrics, we stepped in to define a creative direction grounded in trend and data.

This gave her a visual language for her brand, bridging what she felt with what could be created.

Custom Fabric Development

The core challenge was to find or create fabrics that offered compression, softness, and breathability — a rare combination. Most compression fabrics felt too tight or synthetic.

We initiated custom sourcing trials — experimenting with spandex blends, cotton knits, and sustainable bases.

Introduced bamboo fabric for its silky-soft hand feel, antibacterial properties, and eco-conscious appeal which aligned with her brand ethos and resonated with her target market.

Developed a custom compression fabric that gave structure without stiffness, offering core support for long travels.

Each fabric was tested for:

We didn't just find fabric — we engineered it for her exact use case.

Custom Fabric Development

The core challenge was to find or create fabrics that offered compression, softness, and breathability — a rare combination. Most compression fabrics felt too tight or synthetic.

We initiated custom sourcing trials — experimenting with spandex blends, cotton knits, and sustainable bases.

Introduced bamboo fabric for its silky-soft hand feel, antibacterial properties, and eco-conscious appeal which aligned with her brand ethos and resonated with her target market.

Developed a custom compression fabric that gave structure without stiffness, offering core support for long travels.

Each fabric was tested for:

We didn't just find fabric — we engineered it for her exact use case.

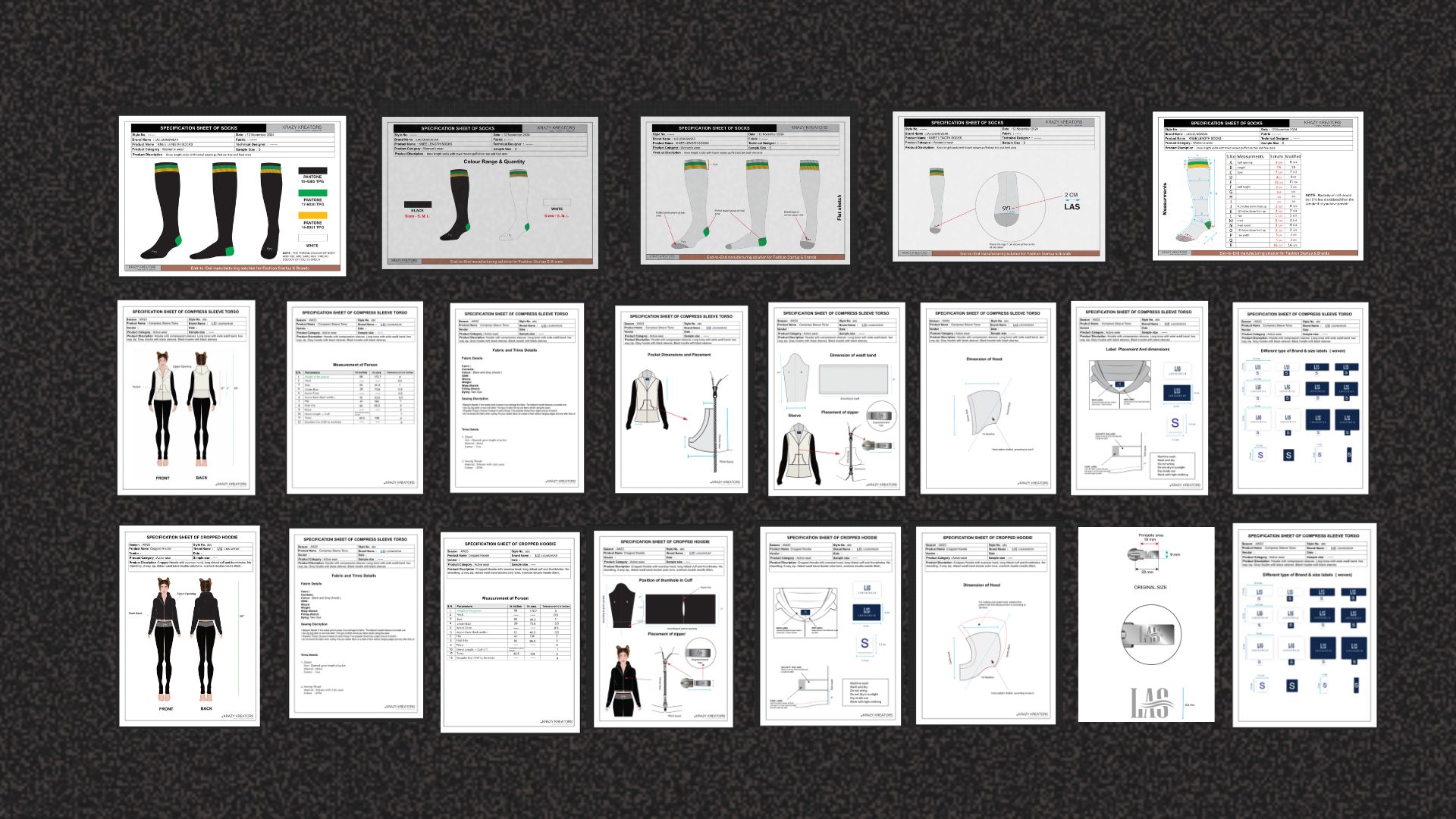

Tech Pack Development

To move from concept to production-ready, we created detailed tech packs for every style.

Included technical flats, spec measurements, fabric consumption, construction details, and trims.

Mapped placement of zippers, panels, elastic zones, and specialty features like satin hoods.

These served as the blueprint for our sampling and ensured all communication with tailors and factories was crystal clear.

Helped avoid guesswork, reduce sampling errors, and increase efficiency in production.

Sampling and Fit Trials

Turning design into product required multiple rounds of sampling and refinement.

Coordinated with master tailors and fabric technicians to create first samples based on approved tech packs.

Conducted fit trials on real bodies — testing wearability, ease of movement, and shape retention after wear.

Incorporated feedback from Anika at every stage — ensuring silhouettes matched her imagination and felt great in real life.

Made multiple sample iterations to perfect minor details: necklines, sleeve finishes, zip placements, and length ratios.

Also tested fabric layering techniques where one style used 3–4 different fabric types — something most production houses avoid due to complexity.

We obsessed over fit, finish, and feeling — because premium wearability lives in the details.

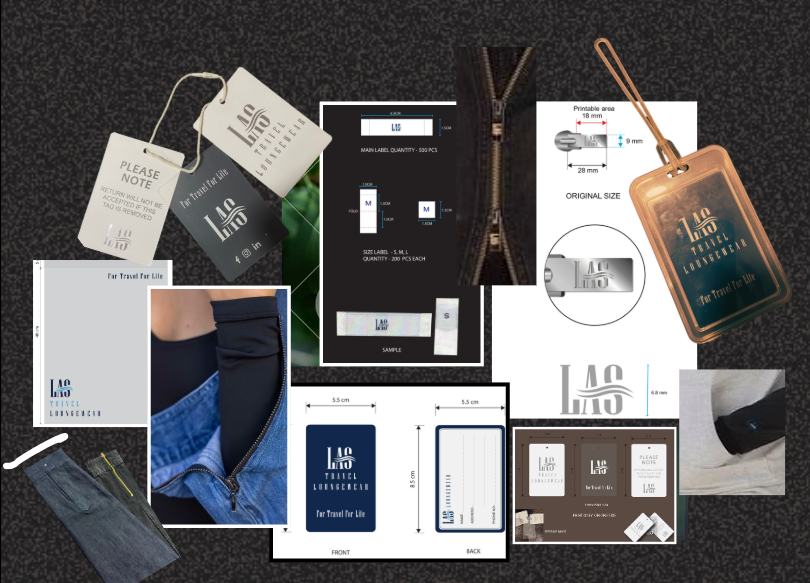

Detailing, Trims & Label Development

Every feature was intentionally crafted, not just functional — but brand defining.

Created custom trims — like branded zippers, contrast tapes, and satin hood linings.

Designed brand labels that felt premium and aligned with her wellness aesthetic.

Carefully selected stitch types, zipper placements, and hardware tones to elevate the look.

Every detail — from neck binding to seam tape — was reviewed for quality, comfort, and aesthetics.

We believe "premium" lives in the smallest details. That's where we focused the most.

Production & Packaging

Pattern Grading

After finalizing approved samples, we moved into pattern grading – adjusting each style into all required sizes while maintaining fit precision.

Every garment was graded keeping fabric stretch, compression zones, and layering functionality in mind.

Production Begins (Low MOQ, High Variety)

We moved into actual production across multiple styles, all managed in low quantities (as per the brand's exclusive model).

Each style had different construction requirements – from multiple fabric combinations to functional details like zippers, drawcords, and hoods.

In-line Quality Check

During production, we implemented stage-wise quality checks: checking stitching, seam strength, fabric alignment, and trim placements in real time.

This reduced the chance of bulk defects and ensured consistency from piece to piece.

Finishing & Detailing

Once stitching was done, every garment went through finishing: thread trimming, steaming, pressing, and hardware adjustment (like zip alignment).

Applied brand labels, size tags, and care labels in exact specified placements for professional presentation.

Final Packaging

Each finished product was then individually packed as per brand packaging guidelines.

We used custom labels, tags, wraps, and polybags, carefully arranged to match the LAS identity – clean, premium, and travel-ready.

Las Loungewear Client Testimonial

“Working with Krazy Kreators was a game-changer for Las Loungewear. They didn't just understand my vision — they elevated it. From the initial concept to the final product, every step was executed with precision and creativity.”

“The attention to detail in fabric selection, the innovative compression technology, and the sophisticated design elements exceeded my expectations. They truly became a partner in building my brand, not just a vendor.”

“The end result is exactly what I envisioned: premium travelwear that feels luxurious and performs perfectly. Our customers love the quality and comfort, and I couldn't be happier with the partnership.”

Anika McKelvey

Founder, Las Loungewear

Miami, USA

Las Loungewear Brand Launch

Explore Our Other Case Studies

Discover how we've helped other brands transform their vision into reality

READY TO BUILD A BRAND THAT

STANDS OUT?

Let's create something timeless, sophisticated, and unapologetically luxurious. Your vision deserves to be celebrated in premium fashion.